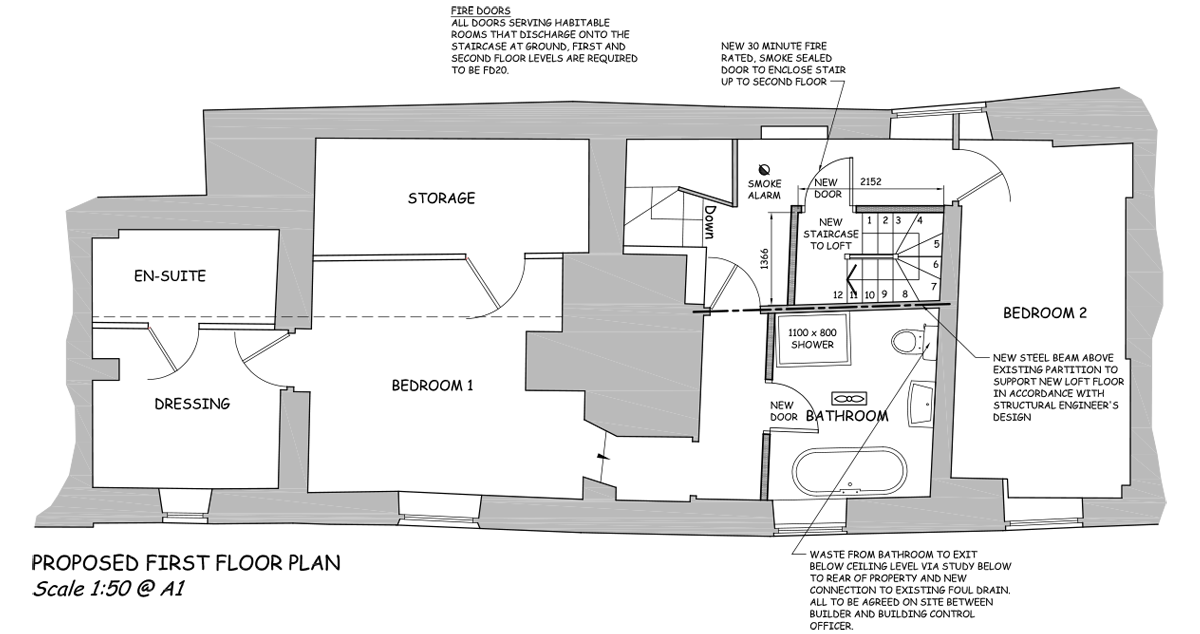

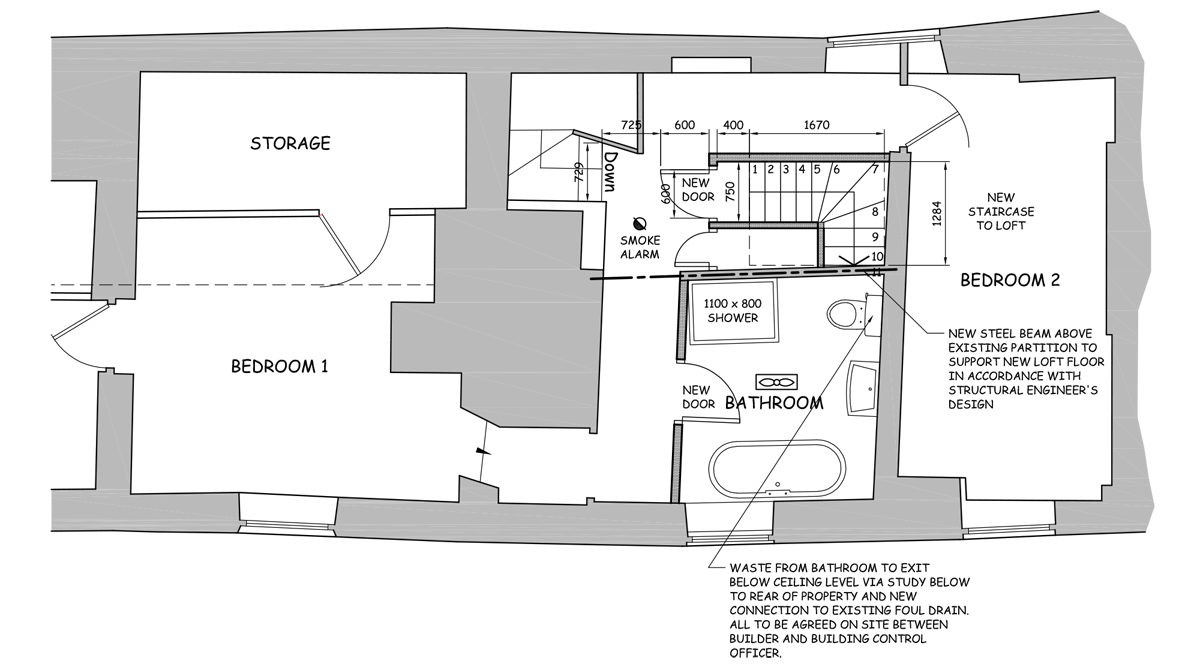

So after many meetings and discussions, measuring up again and again, getting our Architect to redraw our plans (with an L-shaped staircase rather than the U-shaped one) and speak with Building Control to see if they would approve it, the ‘wrong’ staircase is actually going to fit!!!

We were always under the impression that an L-shaped staircase wouldn’t fit as there wasn’t enough space for this and the stud wall to comply with building regulations. Originally we measured the space and discussed our options with many different carpenters, Architects, Structural Engineers, Conservation Officers, etc. and everyone came to the same conclusion, that it would have to be a very narrow U-shaped staircase. When I say narrow, I mean really bloody narrow, the steps would have been around 550mm wide and definitely would have been a tight squeeze (especially for anyone with broad shoulders). The fact that we can get the wider staircase (750mm wide) to fit is a total bonus and a very happy accident!

We must thank Jason at Feldon Joinery for being so insistent that it would fit, we had just dismissed it as wrong, but we now have a much better staircase than we had originally planned. Serendipity at its very best!

So on Tuesday afternoon, only a day after we worked out it was actually going to fit, the carpenters arrived to install it as they had a hold up on another job. Double bonus!

Harvey and Blake from Feldon Joinery manoeuvring the staircase into place.

The top part of the staircase gets hung from the attic floor (where the massive steel beam sits).

Making sure it is in the correct position and attaching a temporary timber support.

Attaching the central oak newel post.

Preparing the second part of the staircase.

Attaching the treads and risers for the 90 degree turn. These get glued in place.

The second part gets fixed in place.

Calculating that it still complies with building regulations.

There must be 400mm from the bottom step to the stud wall and door, then 600mm clear for the door to swing open, then 725mm from this to the top step of the existing staircase. Anything less and building control won’t pass it but thankfully we are okay with just 10mm to spare! We couldn’t tell this until it was built.

All the treads and risers are in.

It was so exciting to walk up this for the first time, we’ve spent months going up and down the ladder!

A temporary support added until the stud wall gets built here. There will be a cupboard under here with a small door.

This gap down the back of the staircase will be filled with a timber fillet.

The oak newel post ready for the spindles and handrail to be added tomorrow.

Tidy workers clearing up after themselves!

At some point today the skip was picked up. I had no idea until I went to put something in it and noticed the gap in the garden.

Wednesday morning and Harvey and Blake return to fit the oak spindles and handrail, setting up their chop saw in the garden.

All done and they remove the Ram Board from underneath the staircase.

I’ve been sending Cat photos during the build but she cannot wait to see it at the weekend. We have waited so long for these stairs to go in.

The spindles, posts and handrail for the balustrade to go around the top in the attic. Unfortunately there aren’t quite enough here to build this today, we shall have to wait until they deliver more next week.

They have made the oak spindles with a stop chamfer to match the rest of our oak and they look fabulous.

Jasper: “What is this magic, this wasn’t here yesterday…?”

Fabulous! So pleased that it worked out xx