A very busy day on site with 8 vans outside our house at one point! Huge apologies to all our neighbours and the driver of the daily bus service.

Tom and Dan are back to fit the insulation in the loft, a job they have not been looking forward to and I now know why! It’s a battle to get this stuff on! All I heard as I climbed the ladder to see them was ‘if your head gets any closer to my crotch…’ from Tom. Cue lots of swearing but also much giggling.

They have to get the insulation down into the bottom of the eaves, the worst part of the job as it is so awkward.

There needs to be two layers of insulation with an air pocket in between. The first layer gets attached into the cavities between each rafter, fixed with battens, then the second layer goes all the way across the top, creating the pockets of air in between the rafters.

The first layer of insulation, fixed with battens in between each rafter.

The insulation is SuperQuilt Multifoil Thermal Insulation, a very thin but very effective insulation, so we can maximise the space available in the attic and not lose any head height.

Trimming the battens down to size.

The insulation gets fixed in place with a nail gun and a grimace.

Jasper checking on progress on site.

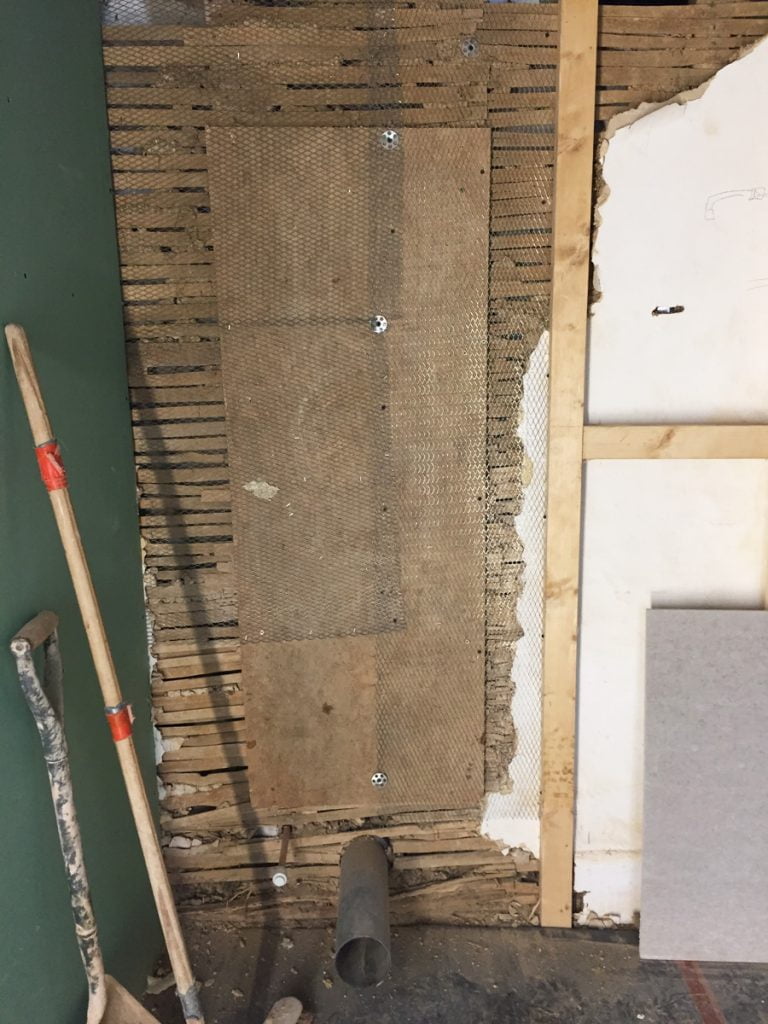

The bathroom wall where the toilet will sit. The plasterers have fixed a piece of chipboard to the wall so we have something solid to fix the toilet to. This is the very old lath and plaster partition wall in the house. It will be protected for posterity behind the plasterboard.

The bathroom taking shape!

The corridor outside the bathroom through to Cat’s bedroom. We have walls! It’s very exciting!

Our plumbers, Billy and Andy are back to re-route the pipe work from the dining room, ready for it to be plastered. These are the pipes that used to feed the bathroom here, they will be moved upstairs and run through the cupboard in the eaves in Cat’s bedroom.

Look at the roof! They are nearly finished on the front!

The tile vent will be fitted when we have one that matches a bit better.

We love the uneven tiles, this is what makes a historic roof distinct from a modern roof, as the tiles are handmade (and old) they are all different. We love it. It would not look right with uniform modern tiles.

The wind has picked up today and Pete is not having fun working on the top of the roof. It’s where the covering has failed so is bloody blowy!

The lead is being added to the cheeks of the dormers.

The lead gets added in two parts (as you can’t get lead in long widths, it becomes too heavy), with the join being reinforced with copper.

Copper nails are used to attach the lead to the timber.

6 white vans and 2 Land Rovers!

Dan and Tom are still battling with the insulation.

Charlie and Mitch adding the first coat of plaster to the ceilings on the landing and in the bathroom.

Alan has the (unwanted) task of cutting and fitting the cement board for the shower in the bathroom. We are using cement board behind the shower as it is super waterproof and super strong so it will be able to take the weight of our heavy tiles.

Billy managing to stop a second explosion of water and orange gunk from the water feed to the kitchen tap. It had already exploded once all over the kitchen walls and window…

Andy re-routing the pipe work from the dining room up into the cupboard in the eaves.

Tea break.

Sneaky cigarette break.

Alan installing the cement board for the niches in the shower.

The window recess has been plastered and the plasterboard has had the joints taped and is ready for the plaster.

The insulation in the attic installed on one side of the room in two layers.

Ready for Halloween.